Hand-Cranking Pencil Sharpener

ZiYang Guo

City College of New York

ENGL 21007: Writing for Engineering

Professor Elisabeth Von Uhl

April 8, 2021

Contents

Introduction.……………………………………………………………………………… 3

Mechanical Parts Clarification.……………………………………………………. 4

Conclusion.………………………………………………………………………………. 7

Reference………………………………………………………………………………… 8

Introduction

In most of our lifetimes, you probably have seen and used a pencil sharpener. Like many other objects that are used for a specific purpose and convenience, a pencil sharpener is part of our schooled lives and it has been a useful tool. Many small tasks in school require a sharpened pencil, so preparing for a test, writing, or drawing, a pencil sharpener will be your best choice. Pencil sharpener came in many different sizes, shapes, costs, and forms. The manual hand-crank sharpener is the best option because of its ease functionally and transportation making it an effective tool to carry and have around you.

Before the first invention of pencil sharpeners, the old technique of pencil sharpening is using knives to carve the pencil, making pencil sharpening a difficult and time-consuming task. Later till the year 1847 a French nobleman by the name of Thierry des Estivaux, “patented his design of the classic tube fitted with a narrowing cone and a blade”(Constant de Thierry des Estivaux, Marquis de Faletans – Inventor of the Pencil Sharpener, 2011). Estivaux’s creation of a prism sharpener is pocket-size, weightless, safe, and easy to compare to knives. Previous prism sharpeners are made of wood and metal, nowadays they are manufactured in hard plastic. Today’s sharpeners use prism sharpener as the inter-component for sharpening, but their outer-tier design cover is manufactured differently. In the later invention of the planetary pencil pointer by A.B. Dick company (1896) and hand-cranking pencil sharpener by John Lee Love (1895). The use of planetary sharpener has two helical cylindrical cutters forming an acute angle with a pencil insertion area. The cylindrical sharpener is still being used in modern hand-cranking and electrical sharpeners.

Mechanical Parts Clarification

Most of the modern-day Pencil Sharpeners may look different from the outsider by the customized design by different companies, but the interior functioning system uses a similar method. This method of design is a planetary system, which is related to the use of planetary gears that does the circular motion around a central point. The system is designed with a pair of cutters that can cut in a 360 degrees motion. And through the activation of circular motion pair with cutters, it becomes a cutting chamber specifically for pencils. In Figure 1 below shown the detached parts of a planetary pencil sharpener, the parts include two helical cylindrical cutters, two screws, one frame-cast, one standing frame, one planetary gear, and one handle. The unmentioned part is the cover frame piece, it functions as a covering up the interior-machineries and defines the outside appearance of the sharpener. Many pencil sharpener companies have their own unique custom design for cover frame piece to present and cosign their creation, but the majority of these companies uses planetary sharpener inside their pencil sharpeners.

The first part of the pencil sharpener design is a standing frame works as a base. That holds up the planetary sharpener and provides a place holder for the installment of the planetary sharpener. The preferred materials for the standing frame are metal or hard plastic for stability and solidity. The standing frame is the back cover frame of a pencil sharpener, the look design is dissimilar for different pencil sharpener companies. The design factors are a wide area of the base to create stability in order to stand up, a 90° angle standing frame created from the base that is standing about three-fourth of the base area, a height of around 7 inches to provide space for storage of pencil scrap, the near top of the standing frame needs a two wayed hole, front and back, the front requires a bigger opening for the installment of planetary gears, and the back is a smaller opening for handle installment. These creation factors will provide a good foundation to build off of when attaching all the pieces of machinery part as one forming the planetary sharpener.

The next building block is the ring gear, an important component of the planetary gear system. A planetary gear set consists of an outer gear ring called the ring gear. “Inside, you have a sun gear that has a fixed point in the center and a planet gear (or gears) that rotate about the sun gear. As they rotate inside of the ring gear, the planetary gears create pitch circles that can be formed into a gear train that, in turn, is hooked up to input and output shafts”(Jeff Glucker, 2017). Planetary gears are made of hardened steel to promote the long use of lifetime and firmness. Implementing planetary gears allows circular rotation to take place, therefore enables hand-cranking motion to move the gears. The ring gear is acting as a track for the helical cylindrical cutters’ gears to run on. This planetary gear system enables the act of transferring the force from hand motion to the sharpening motion. Even though, the ring gear is the smaller piece of mechanical part but provides an important role for functionality.

The planetary sharpener has a skeleton structure, a metal frame-cast that forms the shape of the sharpener and provides support in structuralizing all the parts into one. The design of the frame-cast is for installing and connecting the other parts of the planetary sharpener, such as the handle, screws, helical cylindrical cutters, and planetary gears. Figure 2 shows a frame-cast with helical cylindrical cutters installed. The head of the frame-cast has an insertion area, the hole where pencils get sharpened. On the opposite side, the tail part consists of a thread pitch that is used to install the handle in the later steps. Then, there are screw holes, two screw holes on the left and the right, the screw holes are not aligned on purpose to create two diagonal lines. Diagonal lines are the area of installment for helical cylindrical cutters and screws. Two diagonal lines will form an acute angle with an opening at the insertion area, when the pencil sharpener is in motion the acute angle will form a sharp cone shape. The purpose of this cone shape is to create the ideal shape for the tip/head of a sharpened pencil. All these design factors of the frame-cast help create a structuralize planetary pencil sharpener.

The chef behind the kitchen of pencil sharpener is the helical cylindrical cutter, an object shaped like a helical cylinder with spiral cutting edges. The primary function of the cutting edges is to shear off materials, which is the wood and lead of a pencil. This specific design allows the cutter to cut in a 360 degrees rotation. The helical cylindrical cutter has a planet gear attached to the bottom, the planet gear functions with the ring gear. Helical cylindrical cutters will be installed onto the frame-cast, through the method of passing screws through the screw hole of frame-cast to the helical cylindrical cutter, then the cutters will be linked to the frame-cast as shown in figure 2. above. The planet gears will be attached to the ring gear when the frame-cast is plug into the ring gear and standing frame. The planetary gear system function is connecting planet gears with the ring gear, this increased torque of the sharpener machine which is more working power. The working power is transferred into the motion of sharpening resulting in creating a pencil sharpening chamber.

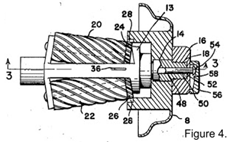

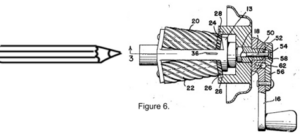

In figure 4. is a structure of the planetary sharpener in a sketched image. A portion of the standing frame is represented by #8, the ring gear #28 (ring gear is represented in the two-dimensional form shown as a small rectangle) is attached to the standing frame. The frame-cast is installed with screws and helical cylindrical cutters (#20 and #22), then is insert and install onto the standing frame with the ring gear attached. The planetary gear system is represented by planet gears (in #24 and #26) and ring gear (#28), the gears are in contact. The ring gear is a disengaging gear and planet gears are engaging gears, the planet gears will run on the track of the ring gear when the spinning motion is activated.

order to obtain the spinning motion, the handle must be installed to the tail of the frame cast. The tail of the frame-cast has a thread pitch (#48 in figure 5.) that will match the internal thread pitch (#18 in figure 5.) of the handle. After the installation of the handle onto the frame-cast, the planetary sharpener is completed. The handle will control the entire planetary sharpener through clockwise rotation cycles.

Conclusion

The invention of a hand-cranking pencil sharpener provided an effective sharpening tool with effortless operating movements. Hand-cranking pencil sharpeners apply the concept of a planetary gear system for circular rotation within the sharpener. In effort to move diagonally placed helical cylindrical cutters and forming a cone shape cutting chamber. This is a major step forward, coming from the origin of using knives to carve a pencil compare to now spinning a handle for pencil sharpening. Even though both techniques of sharpening, knives and pencil sharpener, are manual tasks, the innovation of pencil sharpener made the task of pencil sharpening much more effortless, safer, and less time-consuming.

Reference

A. (Ed.). (2011, July 20). Constant de Thierry des Estivaux, Marquis de Faletans – Inventor of the Pencil Sharpener. Retrieved March 30, 2021, from http://www.rupertwilloughby.co.uk/gleanings/constant-de-thierry-des-estivaux-marquis-de-faletans-inventor-of-the-pencil-sharpener/

Boston KS pencil Sharpener Restoration, Pt. 1. (2016, March 16). Retrieved March 30, 2021, from http://crawlsbackward.blogspot.com/2016/03/boston-ks-pencil-sharpener-restoration.html

C. (2020, December 6). Apsco Vacuhold pencil sharpener 13. Retrieved March 30, 2021, from https://kids.kiddle.co/Image:Apsco_Vacuhold_pencil_sharpener_13.jpg

Glucker, J. (2017, January 10). Classic video explains how a planetary gear set works. Retrieved March 30, 2021, from https://www.motorauthority.com/news/1108196_classic-video-explains-how-a-planetary-gear-set-works

History of pencil sharpener – types and facts. (2021). Retrieved March 30, 2021, from http://www.historyofpencils.com/writing-instruments-history/pencil-sharpener-history/

Look sharp. – present&correct. (2014, January 16). Retrieved March 30, 2021, from http://blog.presentandcorrect.com/look-sharp-3